October 22, 2012

MicroLink Devices in partnership with the Air Force Research Center at Wright-Patterson Air Force Base and UES, Inc. has demonstrated the integration of MicroLink's lightweight, high-efficiency, solar panels onto a small unmanned aircraft system (SUAS) platform. MicroLink's novel solar panels are based on MicroLink's large-area inverted metamorphic multi-junction (IMM) solar cells fabricated through the epitaxial lift-off (ELO) process. These lightweight solar panels were integrated to Raven UAVs and flown demonstrating a 60 percent increases in flight endurance and showing promise for a 100 percent improvement over systems currently in use.

Click the link to see the full article on the Wright-Patterson AFB website.

January 26, 2013

MicroLink Devices in collaboration with the U.S. Naval Research Laboratory and the Imperial College London have proposed a novel triple-junction solar cell with the potential to break the 50 percent conversion efficiency barrier, which is the current goal in multi-junction photovoltaic development.

Click the link to see the full article on the NRL website.

January 25, 2013

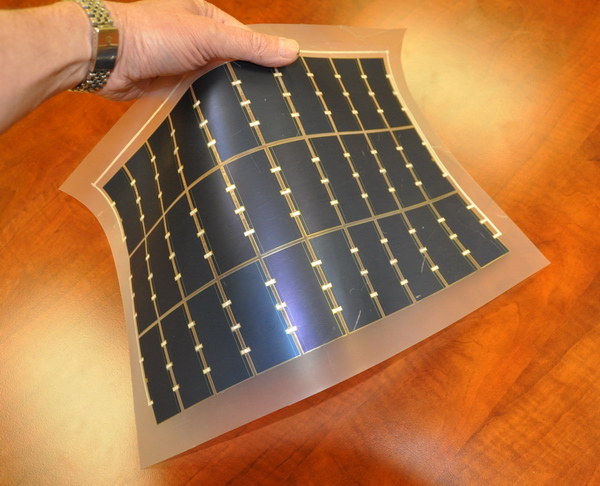

Niles, IL - MicroLink Devices, Inc. (www.mldevices.com), a Niles, Illinois-based semiconductor manufacturer and leader in the development of high-efficiency solar cells, announced that it has developed a lightweight, flexible, high-efficiency solar sheet suitable for powering small electrical equipment off the power grid. The sheet has a conversion efficiency of 29%, generates up to 9.25 watts in a 320 cm2 active area, and weighs 230 grams per square meter. The sheet is highly flexible and can be wrapped around a cylinder a few inches in diameter without damage.

MicroLink’s high-efficiency solar sheet. This sheet contains thirty solar cells, each with area 20 cm2..

The total power generated by this sheet is up to 17.5 W.

The solar sheet is enabled by MicroLink’s proprietary epitaxial lift-off (ELO) technology, in which a triple-junction solar cell is removed from the semiconductor wafer on which it is grown. The solar cell is mounted on a metal sheet, which provides mechanical support to the thin, brittle solar cell material. The efficiency of the 20-cm2 solar cell, which resembles a sheet of thin metal foil, is up to 32.2%. The ELO process permits the solar cell to be removed from the semiconductor wafer without damaging the wafer, which can be reused multiple times. This enables a substantial reduction in the cost of the ELO solar cell compared with conventional triple-junction solar cells.

Dr. Noren Pan, the President and CEO of MicroLink Devices, said, “We are extremely proud to have developed this high-performance solar sheet. We know of no other device that offers a comparable performance in terms of efficiency and weight”.

MicroLink is currently transitioning its solar sheets from research and development to practical applications. In a project funded by the US Air Force Research Laboratory, the solar sheets have been mounted on the wings of Raven unmanned aerial vehicles (UAVs), resulting in a doubling of the UAV endurance. In another project funded by the US Naval Research Laboratory, the solar sheets have been mounted on the backpack worn by a US Marine. The collected energy is used to charge a BB-2590 battery. The goal of the program is to reduce the weight of batteries carried by the Marine.

About MicroLink Devices, Inc.

Dr. Pan co-founded MicroLink Devices in 2000. MicroLink has specialized in the growth of epitaxial structures that are used to make the high performance HBTs and power amplifiers that are essential to the high-speed communications industry. The company has earned ISO 9001 Certification for its quality and service practices. Over the last six years, MicroLink has been a prime federal contractor on projects to develop solar cells, detectors, lasers, and high-speed transistors. MicroLink Devices has also collaborated with many other companies on research and development projects, the results of which have become widely used commercial products.

Contact:

MicroLink Devices Inc.

David McCallum, VP of Marketing

(847) 588-3001

This email address is being protected from spambots. You need JavaScript enabled to view it.

December 21, 2011

Chicago, IL - MicroLink Devices, Inc. (www.mldevices.com), a Niles, IL-based manufacturer of solar cells and sheets, and of wireless communications materials, has received notification that it has been selected for award of three research contracts from NASA. Two of the contracts are SBIR Phase I; one involves high-volume production of lightweight, multi-junction solar cells using 6-inch GaAs; the other involves the development of a lightweight, flexible photovoltaic module. The third contract is STTR Phase I and involves the development of epitaxial lift-off (ELO) photovoltaic devices that contain quantum dots.

According to Dr. Noren Pan, MicroLink’s President and CEO, “We are very excited by these awards. The SBIR and STTR programs are extremely competitive and it is a testament to MicroLink’s innovative solar cell technology and to the quality of its engineering and scientific staff that NASA has awarded us three contracts.” Pan added, “We look forward to the successful completion of these Phase I contracts over the next year and to transitioning the resulting technology into products.

About MicroLink Devices, Inc.

MicroLink Devices, Inc. was founded in 2000 by Dr. Noren Pan, its current president and CEO. The company specializes in metalorganic chemical vapor deposition (MOCVD) growth of semiconductor structures for use in communications devices, and in the growth and fabrication of advanced solar cells for space, unmanned aerial vehicle (UAV), and terrestrial use. MicroLink also performs engineering research and development services: it has collaborated on commercial research and development projects with many other companies, and has been a prime federal contractor on many solar cell, optoelectronics, and electronics projects since 2003. The company has earned ISO 9001 Certification for its quality and service practices.

Contact:

MicroLink Devices Inc.

David McCallum, VP of Marketing

(847) 588-3001

This email address is being protected from spambots. You need JavaScript enabled to view it.