January 5, 2021

MicroLink Devices is pleased to announce that it has been awarded and selected to pitch the following AFWERX projects.

1) Awarded AFWERX Phase I Program: Advance High Specific Energy Power Systems for eVTOL

The Air Force has identified a need for advance power systems to support future manned eVTOL platforms. MicroLink will develop an advance power system utilizing high specific energy Li-Ion cells and high specific power flexible solar arrays now used on solar-powered stratospheric UAVs. New solar and battery technologies from MicroLink Devices and Amprius are a pathway for advance energy generation and storage solutions that will significantly increase the flight endurance and capabilities of emerging eVTOL platforms. In Phase I and with support from the Aerospace Engineering Department at the University of Illinois at Urbana-Champaign, a high specific energy power system will be demonstrated that will enable greater range and capability for emerging eVTOL platforms not possible with current battery technologies and the means for charging the platform while in flight or away from base will be shown further increasing flight time, range, and capability.

2) Selected for AFWERX Showcase: Space Qualification of MicroLink ELO Multijunction Solar Cells

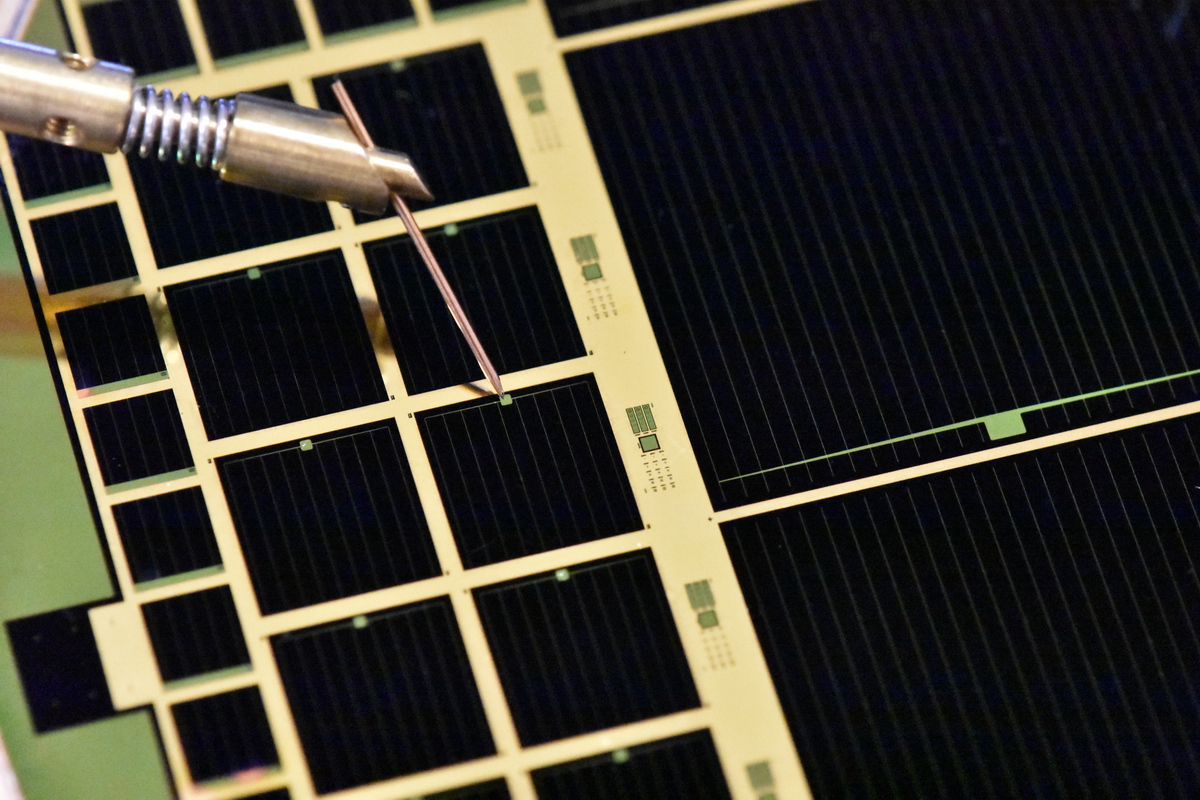

MicroLink Devices will begin space qualification for its high efficiency epitaxially lifted off (ELO) IMM (inverted metamorphic) solar cells following AIAA-S111 & S112 standards. MicroLink's ELO solar cells have highest specific power >2000 W/Kg and exhibit AM0 efficiency exceeding 30%. Current space-based energy harvesting technology uses solar cells grown on Ge substrates that are neither flexible or lightweight. Several consortiums are currently developing small satellites for use in large constellation systems for low orbit deployment. These systems require a solar technology that is low cost, flexible, and lightweight. MicroLink's ELO solar cells are ideally suited as they are cheaper to manufacture and produce more power. By providing AIAA qualified ELO IMM cells to the satellite industry, an alternate and low cost photovoltaic solution that is reliable will be available to the growing space market.

About MicroLink Devices:

MicroLink Devices is an American owned company located in Niles, IL. Dr. Noren Pan cofounded MicroLink Devices in 2000. MicroLink has specialized in the growth of epitaxial structures that are used to make the high performance HBTs and power amplifiers that are essential to the high-speed communications industry. MicroLink is an ISO 9001 certified semiconductor manufacturer. Over the last eight years, MicroLink has been a prime federal contractor on projects to develop solar cells, detectors, lasers, and high-speed transistors. In recent years, MicroLink has ramped up the production of its ELO-based solar cells and sheets for use in mobile power generation applications.

Contact Information:

This email address is being protected from spambots. You need JavaScript enabled to view it.

October 9, 2019

MicroLink Devices, a leader in the production of high-efficiency, flexible solar arrays for satellite and aircraft, was recognized by Airbus Defence and Space as a key supplier for the Zephyr High Altitude Pseudo-Satellite (HAPS) UAV platform. MicroLink and Airbus celebrated this event with employees on October 1, 2019, in a ceremony near MicroLink’s Chicago headquarters.

MicroLink Devices manufactures a high-efficiency solar sheet product line that is an enabling technology for electrically powered UAVs and pseudo-satellites which have significant area and weight constraints. The combination of high-efficiency and low mass enabled by MicroLink’s epitaxial lift-off (ELO) inverted metamorphic multi-junction (IMM) solar cells provides superior performance unmatched by any other solar cell technology. The latest generation of MicroLink solar sheet products has specific powers exceeding 1.5 kW/kg. The development of MicroLink’s ELO technology over the past decade has been sponsored by numerous U.S. agencies including NASA, DARPA, the Air Force Research Laboratory, the Office of Naval Research, NAVAIR, Army Research Office, Army REF, CERDEC, and the Department of Energy/NREL.

“We are very grateful to Airbus to have had the opportunity to partner with them in making continuous, multi-month solar-powered flight possible through the Zephyr platform,” said Dr. Noren Pan, President and CEO of MicroLink Devices. “Our proprietary solar cell technology provides unrivalled performance in a lightweight, flexible format and is a critical technology for the success of HAPS platforms. MicroLink looks forward to scaling up its production of IMM solar cells to support the exciting emerging markets enabled by the Zephyr platform.”

September 27, 2019

MicroLink Devices, a leader in the production of high-efficiency, flexible solar arrays for satellite and aircraft, announced today that it has completed delivery of its first production contract of solar arrays to Prismatic Ltd. for integration into their PHASA-35 high-altitude, long-endurance unmanned aerial vehicle (HALE UAV). These lightweight, flexible solar arrays have the highest specific power of any solar technology and enable the PHASA-35 to fly for months at a time powered by sunlight alone.

The solar cells incorporate three semiconductor materials with different bandgaps in a single, ultra-thin and lightweight structure that enables greater than 30% of the sunlight to be converted into electrical energy. This high conversion efficiency has previously only been available for high-cost satellites using rigid and heavy solar cells. MicroLink's patented inverted metamorphic multijunction (IMM) technology enables the manufacture of high efficiency devices in a thin and flexible format that produces over 2.0 kW of power from each kilogram of solar cell material.

"Solar powered HALE UAVs rely on the ability to transform as much power from the sun as possible on the limited areas of the wing and to do this with the minimal amount of weight," explained Prismatic's CTO, Dr. Darryl Sergison, "The triple junction structure enables effective partitioning of the solar spectrum for energy conversion whilst MicroLink's lightweight design has proven itself to minimise the mass of this power generation."

Dr. Noren Pan, President of MicroLink Devices noted the synergy of MicroLink's technology with HALE UAV requirements, "Our proprietary solar cell technology provides unrivalled efficiency and low mass, which is critical in ensuring that these new HALE UAV systems can deliver the highest level of performance year-round over the widest possible markets. MicroLink is well-positioned to scale up the production of IMM solar cells to support the exciting emerging markets enabled by HALE UAV over the next few years."

April 18, 2018

MicroLink Devices, Inc. has achieved a 37.75% power conversion efficiency from a three-junction epitaxial lift-off (ELO) thin-film solar cell. The device performance was officially certified by the National Renewable Energy Laboratory (NREL) and tested under the industry standard air mass 1.5 global (AM1.5G) simulated 1-Sun solar spectrum. The 37.75% efficiency is the highest reported for a triple junction ELO solar cell produced on a 6-inch GaAs substrate production platform. The specific power of this ELO solar cell design exceeds 3000 W/kg under 1-sun AM0 spectrum, which is the world’s record in comparison to any other solar cell technology. These solar cells are currently used to provide energy to the Zephyr HALE (High Altitude Long Endurance) platform produced by Airbus Defence and Space in Farnborough, UK. MicroLink has an exclusive licensing agreement with NREL for the inverted metamorphic multi-junction (IMM) technology used to manufacture the high-efficiency solar device.

MicroLink’s proprietary ELO process makes it possible to peel off thin layers of active solar cell material that were deposited on a GaAs semiconductor substrate. The expensive GaAs substrate can also be reused multiple times to lower manufacturing costs. MicroLink’s ELO technology development has been supported over the past decade by numerous US agencies including NASA, DARPA, the Air Force Research Laboratory, the Office of Naval Research, NAVAIR, Army Research Office, Army REF, CERDEC, ARPA-E, and the Department of Energy.

“We are continuing to push the limits of what can be achieved with the ELO technology,” said Dr. Noren Pan, founder and president of MicroLink Devices. “Our triple-junction IMM ELO solar cells combine the highest efficiency with the lowest mass density of any solar cell technology available today. This represents a compelling solution for demanding unmanned aerial vehicle and satellite applications.”

More details about the record ELO cell performance will be presented at the upcoming Space Power Workshop in Los Angeles (April 23-27) and IEEE Photovoltaics Specialists Conference in Waikoloa, HI (June 10-15).

About MicroLink Devices:

Established in 2000, MicroLink Devices is located in Niles, IL and specializes in the design, epitaxial growth and fabrication of compound semiconductor devices including heterojunction bipolar transistors (HBTs), solar cells, lasers and photodetectors. In recent years, MicroLink has ramped up the production of its ELO-based solar cells and sheets for use in mobile power, unmanned aerial vehicle (UAV), and traditional satellite applications.